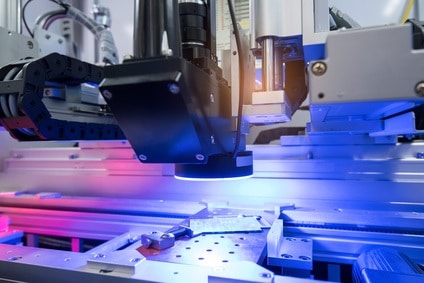

Industrial Vision Systems by RSIP Vision

RSIP Vision’s nondestructive testing techniques and industrial vision systems provide a means of detecting and examining a variety of surface flaws, such as corrosion, contamination, surface finish, and surface discontinuities on joints, bonds and cracks. For example, algorithms developed by RSIP vision’s engineers are currently successfully integrated in automatic detection of defects in ceramic tiles on the production line. We utilize cutting edge algorithms that learn the geometrical properties of each tile, and apply this knowledge to classify fault and assess the severity. The software can spot minute defects while taking into account the wide-range of faults a tile might have, such as low contrast stains, defective printing and broken corners. This vision system prevents defective tiles from reaching final production stages, reducing the cost to the manufacturer while increasing channel satisfaction.

Another prominent examples is the non-destructive inspection during manufacturing of printed circuit boards (PCBs). Owing to the increase of component density, higher demands are placed on errors tolerance during the PCB printing. To this end, the requirements from inspection systems have been placed in tight error margins, for which RSIP Vision has designed algorithms to detect and characterize fault at high precision, using combination of pattern recognition, machine learning and computer vision techniques. Algorithmic solutions to inspection problems increases the affordability of non-destructive vision-based inspection system, owing to the advanced techniques allowing to extract more information from an image than was previously possible. RSIP Vision’s machine vision inspection systems can also be used for other purposes: to ensure that all components of a circuit board have been assembled correctly; to verify that packaging is filled as it should be and that shapes, patterns and alignment are correct; and to check that there are no defects in a silicon chip mask before it is used in production.

To learn more about RSIP Visions project in the field of inspection, please visit our Optical Inspection project page. To contact our consultants, please visit our contact page.