Automated Defect Inspection Using Deep Learning

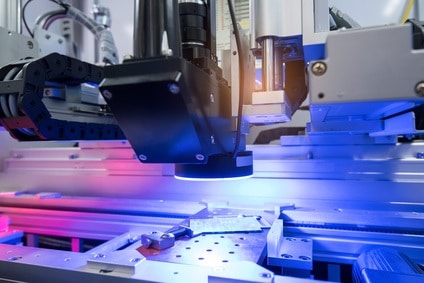

Industrial Vision Systems

During the past few decades, industrial automation of manufacturing processes has taken a great leap forward. Specifically, the increased quality of yield is due, in

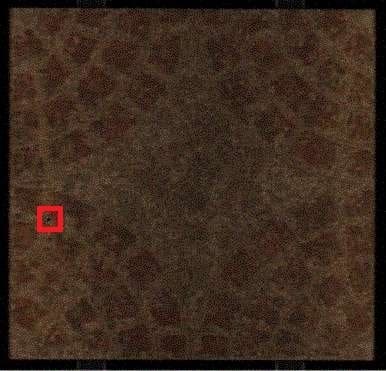

Defect Detection in Ceramics

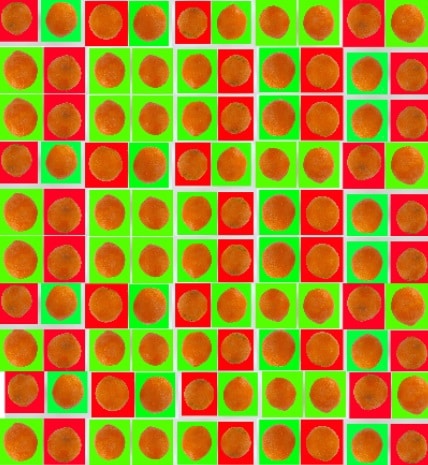

Grading and sorting

Visual Inspection of Semiconductors

Machine fault detection and classification

Automatic detection and diagnosis of various types of machine failure is a very interesting precess in industrial applications. With the advancement of sensors and machine intelligence,

Fabric Inspection with Texture Analysis

Vision-based production inspection systems using camera-based scanning are now quite common in in-line production lines such as in steel, leather and fabrics manufacturing. Inspection is a crucial process since it can reduce process and enhance product quality. We recommend here a texture analysis for defect and novelty detection in fabrics and non-structured surfaces. Our fabric inspection algorithms are developed to detect deviations from local pattern and texture, anomalies and defects.

3D inspection and crack detection