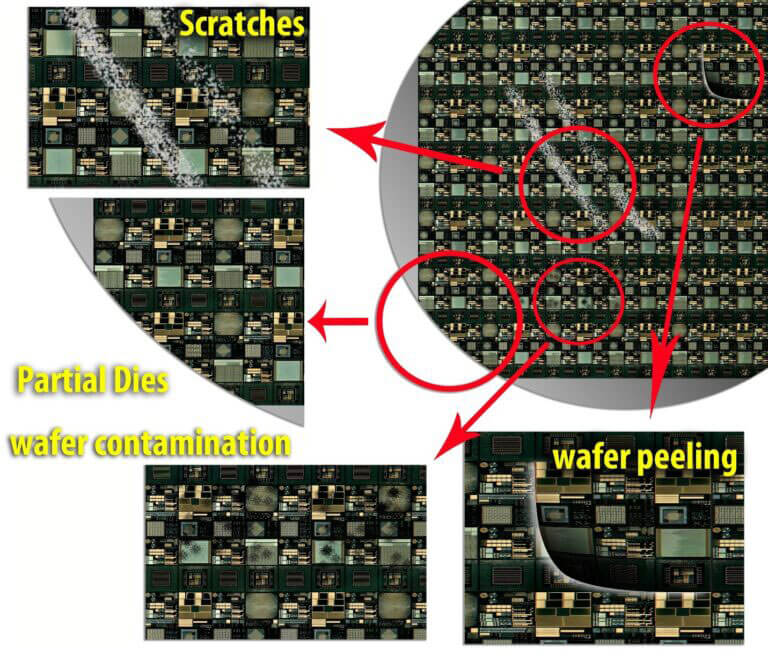

Wafer Macro Defects Detection and Classification

Machine Vision Robots for Semiconductors

Machine vision algorithms are also used to operate robots in the high-precision semiconductor industry. Robots perform these intelligent tasks supported by machine vision software: several methods are currently used to detect defects and classify them, with important economies in both time and money. Robots in the semiconductor industry too can take advantage of deep learning techniques: their main benefit is the dramatic improvement in the defect classification abilities of the robotic devices.

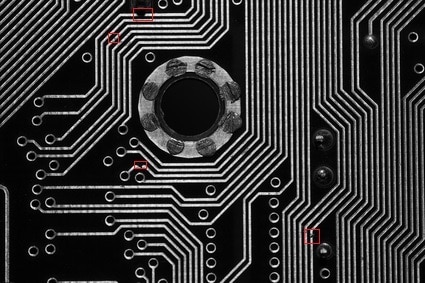

Visual Inspection of Semiconductors